Loading Dock Design and Planning Series 1

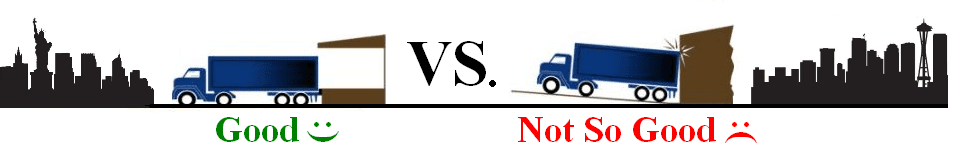

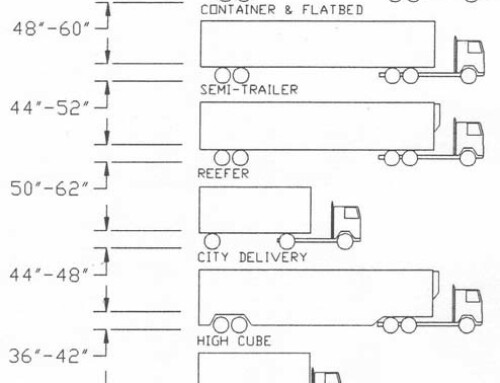

The proficient stream of products in and out of facilities is vital in today’s extremely competitive world. Special consideration must be given to the loading dock area design for this to happen. When coordinating dock heights and door sizes, and when selecting the proper loading dock equipment, there are a number of factors that must be carefully considered.

Dock Access

The Following information is a guideline for applying truck service to the  loading dock area to insure proper design, safety and service to your loading dock area. Apply proper Traffic Engineering design standards and compliance with local codes.

loading dock area to insure proper design, safety and service to your loading dock area. Apply proper Traffic Engineering design standards and compliance with local codes.

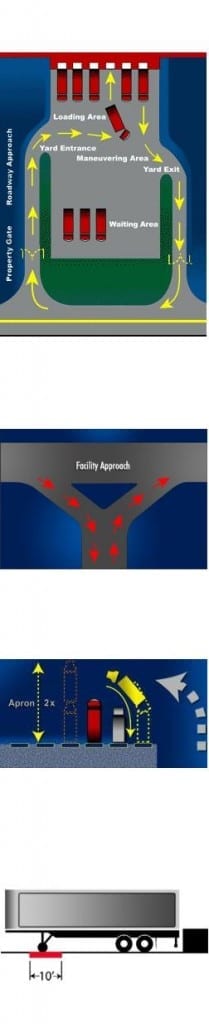

Property Gates

Suggested minimum width at gates leading into approach roadways is 16? to 20? for one-way traffic, 30? to 32? for two-way traffic, and 38? if pedestrian walkway is to be included.

Roadway Approach

Trucks should be permitted to drive in rather than back in. Straight-through, “Y” or angle approaches should be considered depending on traffic volume estimates.

If mixed passenger car and pedestrian traffic is involved in the approach, suitable separation and safety precautions should be planned for.

Yard Approach

Service roads for one-way truck traffic should be a minimum of 14? wide… for two-way traffic no less than 26? wide. If pedestrians are to be accommodated, there should be an additional 6? lane separated from the roadway by a physical barrier.

If a right angle intersection is required, a 50? radius should be planned for commercial vehicles.

The design of approach roadways should also allow for counterclockwise traffic circulation since it is easier for drivers to make left-hand turns and to back trailers into a dock from this position.* NOTE: Traffic directions and illustrations on this website are based on trucks with left-hand drive.

Apron Space

The configuration of the area required to maneuver and position trailers into place is called the apron space. Planning apron space requires recognizing trailer movement and the amount of room it takes to achieve that movement.

Traffic flow and vehicle length are key factors for consideration (i.e. a truck with an overall length of 65? requires a minimum apron space of 135?).

Landing Strip

If the area is to be surfaced with asphalt, a concrete landing strip must be poured. In warm temperatures, the landing strip will prevent the trailer’s landing gear from sinking into the asphalt when spotted. Typical position of semi-truck landing gear is 120? behind the nose of the trailer. Gravel-covered apron space should be avoided because it creates uneven, unsafe conditions.

Waiting Area

Unless docks are designed to handle peak loads, provision must be made for a truck waiting area. This should be placed so that the trucks in this area do not interfere with trucks maneuvering into or pulling away from the dock.

Pavement Surfaces

These surfaces should be specified to be evenly laid and structurally sound to support heavy wheel loads. All roadway surfaces should be slightly crowned and properly equipped with drainage outlets.