Last week I had a customer ask me how to properly calculate the grade of a declined dock approach to their loading dock. As I’m fairly certain they are not alone, I figured this was the perfect opportunity for an educational blog.

My customer was in the process of ordering a dock shelter to accommodate his dock leveler and wanted to ensure it was applied correctly to their approach. As you’ll learn in just a moment, calculating the grade for a declined dock approach is rather easy.

The two most common approaches to a loading dock are level, and declined. In a perfect world, all loading docks would have a very slight incline to let water travel away from the building. The incline would be so minimal that these docks would still be considered a level approach.

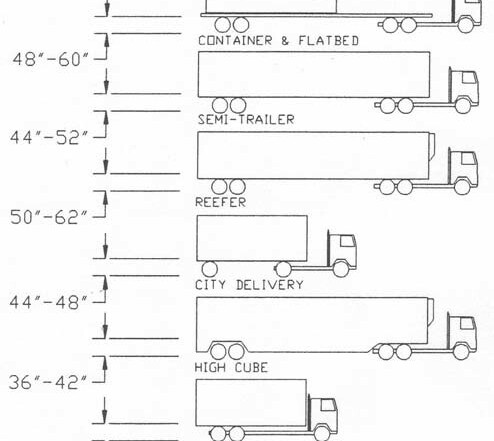

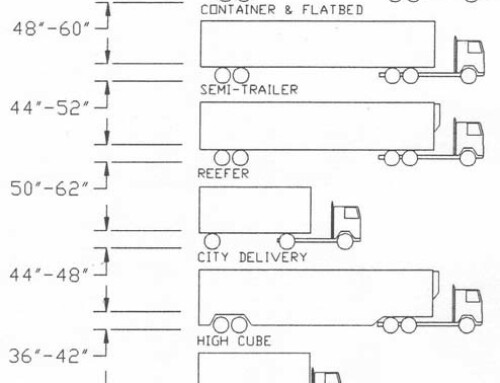

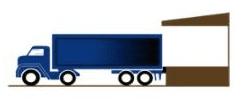

As seen in the picture below, a majority of loading dock’s have a standard level approach with a standard dock height of 48″. A large percentage of these level approach docks will only require a basic dock seal with 4″ bumpers and a 10″ projection on the seal.

If you are one of the many business’ working with a declined loading dock approach as seen below, follow the 5 easy steps within to calculate your grade.

A little vocabulary before we begin:

A little vocabulary before we begin:

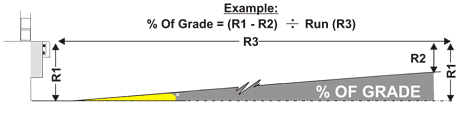

Rise: is the difference in elevation between the loading dock curb and a predetermined point in front of the loading dock.

Run: is the actual distance in front of the dock where the second measurement is taken. For example purposes, I will use 53′ as the predetermined point in front of the dock. I chose 53′ because the freight trailers I service at my loading dock are a max of 53′ long.

How To determine percent of grade

***Be sure to use the same unit of measurement when calculating your grade. To convert the 53′ to inches simply multiply 53 x 12, and use the resulting number of 636 when dividing your numbers.***

1) Take a measurement from the loading dock curb to the ground in front of the dock. This will become the R1 measurement. A standard height loading dock will equal 48″ up from the ground.

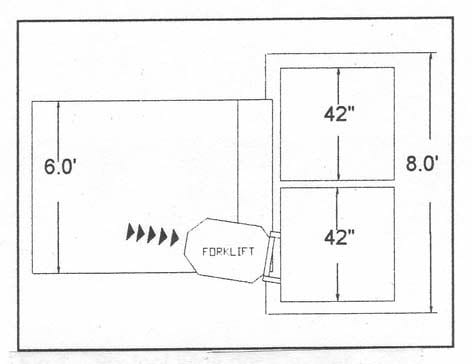

2) Tie a 53′ long string to the lip hinge on top of the leveler or edge of dock (see photo). This 53′ length will become the R3 measurement.

3) With the string in hand, walk 53′ straight out into the driveway of the loading dock. Using a hand held level or string level, find the level plane and then bring your string to the underside of the level. Now take a measurement from the string to the ground beneath, and record that number as the R2 measurement.

4) We can now run the numbers and calculate the percent of grade. Take the 3 measurements you’ve compiled above (R1, R2, R3) and enter them into the following mathematical formula, R1 – R2 ÷ R3 x 100 = % of Grade. Take the end result of that equation and round it up or down to the nearest whole number.

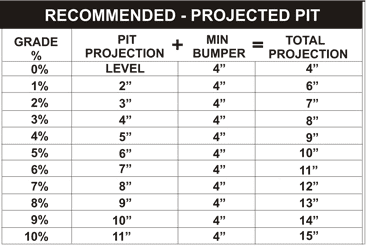

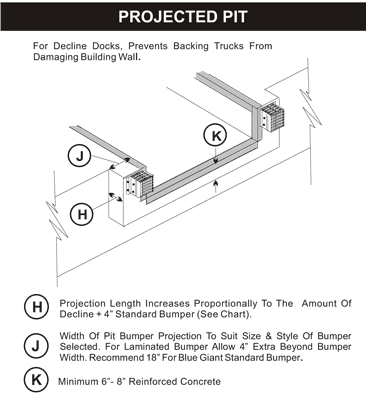

5) The very last step is to cross reference the % of grade on the “Recommended – Projected Pit” table below, and find what the total pit projection should be for your dock seal or shelter.

It is Strongly Recommended for 1%-3% of Grade, Bumper Projection May Be Required Using Build Out Blocks, Extensions or Thicker Bumpers. Consideration of Lip Purchase is Required if Existing Installation. Minimum 4″-6″ Lip Purchase on Trailer Bed is Required.

Warning! Spotting Tractors (Yard Jockeys) When Used At The Loading Dock To Switch Trailers, Creates a Momentary Decline Slope. This is Due To The Front Of The Trailer Being Lifted, Which in Turn Tilts The Back Of The Trailer To The Building. This Creates Lack Of Bumper Projection, Which Can Damage The Building And Injure Personnel.

Here is an example

The measurement of R1 at the dock measured 48″. I chose to use 53′ for my run (R3) as my facility works with full size 53′ LTL trailers most of the time. My R2 measurement = 24″

*Before running the numbers, I convert the 53′ to inches. 53 feet x 12 inches to a foot = 636″. 636 will be our new R3 figure.

Moving forward, subtract 24″ (R2) from 48″ (R1), and divide the difference of 24″ by 636 (R3) to give us a number of 0.037. Multiply .037 x 100 to arrive at our true grade of 3.77%, and then round up or down to the nearest whole number; 4% in this case.

The very last step before placing an order is to cross reference the grade percentage of 4% to the “Recommended – Projected Pit” chart above. According to the chart, I should build my dock leveler with a 5″ projected pit, and a minimum 4″ bumper for a total projection of 9″.

If you would like more information on dock seals and shelters, or would like to place an order, please call our Sales team at 800-724-4052 or click here to send an email.

Beaton Industrial is a proud supplier of Blue Giant Loading Dock Equipment